Manufacturing Capabilities

Our various capabilities allow us to manufacture custom parts at low or high-volume. We formulate the synthetic rubber, mill the material, cut, and form. Our press sizes allow us to manufacture a wide range of product sizes and varying levels of production volume. Our sheet presses enable the manufacture of rubber sheets to be used in various applications such as industrial matting, sound dampening, etc.

We also bond rubber to metal, over-mold metal, reinforce parts with various types of fabrics, and paint parts. Parts can be modified as required with post-mold operations.

Milling & Preforming

Proprietary synthetic rubber formulations are milled and cut in-house and tested immediately before going into production.

Compression Molding

Pellets are placed in heated molds for shaping and curing. Over-molding can be done with different materials (rubber compound or metal inserts).

Transfer Molding

Sheets are placed in the mold and heated. The rubber is injected into the mold cavity. This process is generally used for tighter dimensional tolerances.

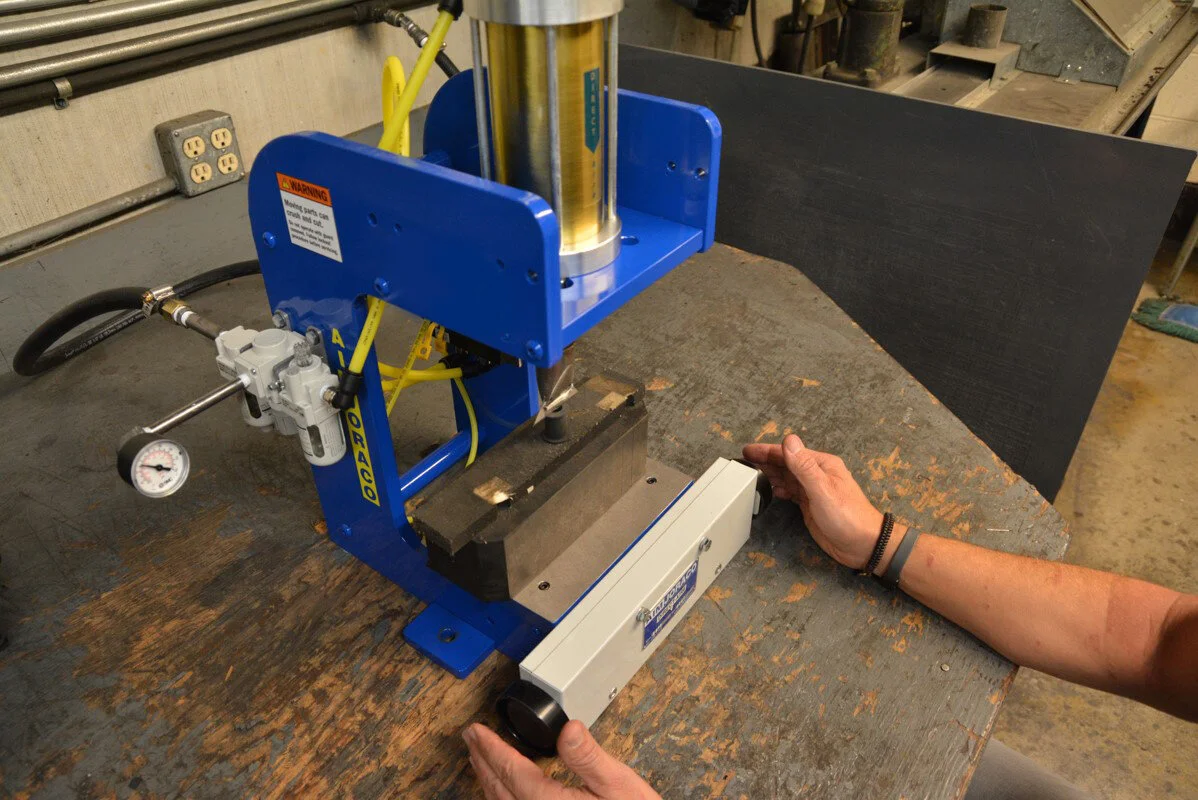

Die Cutting

Polymer sheets are placed in large presses to be cut to size and shape. These sheets may have adhesive backing.

Finishing

Part finishes can be performed as required including drilling, punching, grinding, and cryogenic tumbling.

Painting & Coating

We can paint parts and spray coat metal inserts in our spray room.

Assembly

Our secondary operations also include light assembly as required.

Made in USA

Our quality manufacturing takes place in

beautiful Western North Carolina

![IMG_6653[1270].jpg](https://images.squarespace-cdn.com/content/v1/5f120343e2e15e30b3a58f7b/1599069586836-N2FEZYEOYIVDSMAZ61H6/IMG_6653%5B1270%5D.jpg)

![AAA_2017b[1168].jpg](https://images.squarespace-cdn.com/content/v1/5f120343e2e15e30b3a58f7b/1598992045282-CJT2SEICDKKHI3AF0UX5/AAA_2017b%5B1168%5D.jpg)

![AAA_2000b[1172].jpg](https://images.squarespace-cdn.com/content/v1/5f120343e2e15e30b3a58f7b/1598992103126-16XTWY10DDFEHCS4NJA0/AAA_2000b%5B1172%5D.jpg)